|

|

|

|

|

|

|

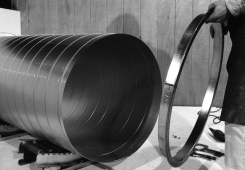

Round AccuFlanges are manufactured as a solid ring. The 2“ leg is a male slip small end stretchout approximately ( = nom dia - 0.20” ) Round AccuFlanges are manufactured as a solid ring. The 2“ leg is a male slip small end stretchout approximately ( = nom dia - 0.20” ) |

|

Start make end of ring by inserting the 2“ leg inside the duct. Start make end of ring by inserting the 2“ leg inside the duct. |

|

|

|

|

|

|

Seat the ring flush with the end of the duct and clamp off into position. Seat the ring flush with the end of the duct and clamp off into position. |

|

Begin securing the leg of the ring to the duct section by placing a #8 or #10 tec screw, spot weld, or pop rivet within 1“ from the face of the flange, 10“ on center around the circumference of the duct. Begin securing the leg of the ring to the duct section by placing a #8 or #10 tec screw, spot weld, or pop rivet within 1“ from the face of the flange, 10“ on center around the circumference of the duct. |

|

|

|

|

|

|

Optional mig welding around AccuFlange to duct 10“ center. Assure button welds cover 50% onto duct and 50% onto flange for a strong weld. Optional mig welding around AccuFlange to duct 10“ center. Assure button welds cover 50% onto duct and 50% onto flange for a strong weld. |

|

Seal lap joint internally with approved duct sealer used in the HVAC industry. Brush the sealer into the joint achieving a 100% seal. Seal lap joint internally with approved duct sealer used in the HVAC industry. Brush the sealer into the joint achieving a 100% seal. |

|

|

|

|

|

|

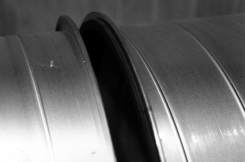

Apply neoprene gasket 5/16“ thick by 3/4” wide to the face of round AccuFlange parrallel with inside edge. Apply neoprene gasket 5/16“ thick by 3/4” wide to the face of round AccuFlange parrallel with inside edge. |

|

Apply neoprene gasket completely around one of the AccuFlange ring to the beginning point. When the gasket meets, cut square so the ends butt up against each other. Apply neoprene gasket completely around one of the AccuFlange ring to the beginning point. When the gasket meets, cut square so the ends butt up against each other. |

|

|

|

|

|

|

Align mating frames by matching the AccuFlange ring evenly around the circumference. Align mating frames by matching the AccuFlange ring evenly around the circumference. |

|

Clamp the mating Accuflange rings compressing the gasket until the mating rings touch. Clamp the mating Accuflange rings compressing the gasket until the mating rings touch. |

|

|

|

|

|

|

Fasten #10 tec screws 6" on center around the circumference of the flange face. In order to assure a proper closed joint, the rings should be clamped tightly together with the two faces touching each other prior to fastening the tec screw. Proper care should be taken in setting the clutch adjustment of your screw gun to assure your screws have 100% holding strength. Fasten #10 tec screws 6" on center around the circumference of the flange face. In order to assure a proper closed joint, the rings should be clamped tightly together with the two faces touching each other prior to fastening the tec screw. Proper care should be taken in setting the clutch adjustment of your screw gun to assure your screws have 100% holding strength. |

|

Round and oval AccuFlange can be installed on reducing fittings in the same manner as a small end collar. This eliminates the need for collars unlike other traditional flange connecting systems. Round and oval AccuFlange can be installed on reducing fittings in the same manner as a small end collar. This eliminates the need for collars unlike other traditional flange connecting systems. |